Studio #507 has been my work space and also my living arrangements for 13 years.

After my second marriage ended in 1999, I took up residency here to nurse my troubled heart and to ease the financial burden on my pocketbook. Towards the end of the 1990's, the fair circuit was slowing down.

Looking back over the years I see a trend that happens every ten years or so. Business at a location is good and then it tapers off. The past 64+ years has taught me to live within my income and not to take my health for granted.

I've learned that a good leather worker has to have an in-depth knowledge of machines. Here is some pictures and descriptions of the machines that I use on a daily basis.

|

| Roller Foot Sewing Machine for Flat Goods |

|

| Compound Feed Sewing Machine Used to Combine Heavy Pieces |

|

| Straight Edge Folder to Turn Edges Automatically |

|

| Large Embossing Machine Produces Heat and Pressure |

|

| Some of the Many Handmade Embossing Dies |

|

| Smaller Embosser Which Enables Finer Detail |

|

| Model-C Clicker Used To Cut Leather With Cutting Dies |

|

| Power Hammer Used To Flatten Seams |

|

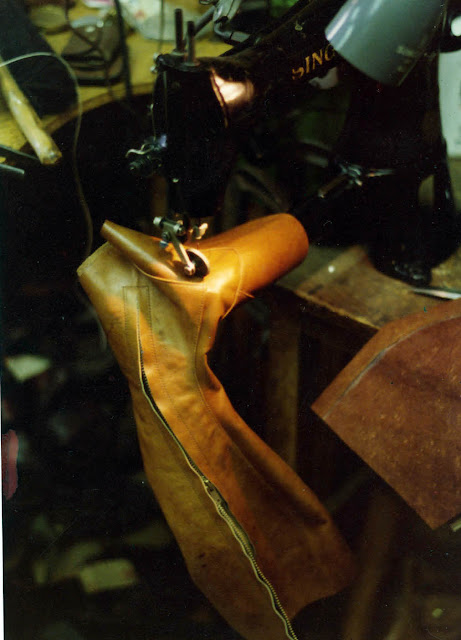

| Cylinder Arm Sewing Machine-Compound Feed |

|

| Compound Feed Post Sewing Machine. |

|

| Skiving Machine Used To Thin Leather Edges |

|

| Kick Press Used To Set Rivets or Snaps |

|

| Hand Turned Strap Folding Machine |

I'm still very much enamored with being a leather worker and have enjoyed every year spent perfecting my techniques. In the late 1990's with urging from my daughter Ann Marie I bought my first computer. I have to honestly say that at first I was terrified of the prospect of learning about computing. As we all know, the learning curve can be steep when it comes to computing by I stuck with it and became very proficient. Photography has always been a hobby and I took many a pictures with my 35MM film camera. With the advent of the digital age and my knowledge of computers my hobby became a driving force of reasons to learn as much as I could about computers. Early on when I chose a computer platform I was advised to choose an Apple product. That advice was invaluable and I'm sure it saved me from many frustrating moments my Window's brethren endure. And thanks to the typing program Mavis Beacon I still am a hunt and peck typer.

The iconic building my leather studio is in is called The Arts Building. A woman named Joan Julien bought this old vacant manufacturing building in 1982-83. With much effort and forethought, she transferred this building into a vibrant home to many artists and craftsman. I relocated here after leaving my home studio in Glendale. I remember that this space had no windows of any kind but Joan put in a window for me. Here is a view from my window and I must say I never get tired of looking out this window. Between the view of the train tracks and the skyline to the east has given me many reflective moments. If you look in the lower right hand corner you can see my white trailer that I use to carry my leather goods in to the various shows I participate in.

|

| This View Looks Out My Studio Window Towards The Southeast - 2012 |

The Arts Building has not only given many artist and craftsman a place to create but thanks to many individual tenants here who organized our Studio Art Crawls. Since this building was home to so many creative people, an idea was floated to have an open house to sell our wares. From 1985 through 2010 the building opened it's doors to customers who flocked to our studios to purchase and observe where we created our various goods. The building was home to many a potter, painter, sculptures, leather workers and glass artists. A woman who worked for me at The Leather Shop was one of the first persons to rent a space at this building. Her name is Ilze Heider and she has since left the building and relocated to a lovely studio on the Milwaukee River in Grafton, Wisconsin. Ilze was a driving force for the Leather Shop she was equally dynamic at developing the Studio Art Crawl. Along with Ilze some of you might know of the artist Don Nedobeck. His whimsical animal drawings are in many homes and offices throughout the USA. When Don had his artist space here in the Arts Building he would entertain the crowd during the Studio Art Crawls by playing his clarinet in his dixieland styled band. The Studio Art Crawl was very unique and received local and international news coverage.

During one of the art crawls I was out of my studio and my daughter Ann Marie was in charge of sales. When I returned she told me that she was sure that the basketball player Larry Bird had just left my studio. I quickly went down the hall to seek him out and only then did I find out that our very tall mayor, John Norquist had just been mistaken for Larry Bird. We all had a good chuckle with that.

Over the years the Studio Art Crawl was a successful and well attended event but in 2010 the event ended. More and more vacant buildings in the area were being renovated into condos or apartments and filled with tenants. Parking was becoming a premium, sales were slowing down and the energy it took to put on the Art Crawl was diminishing. It had a great 25 year run!

Around 1999-2000, the original owner of the Arts Building, Joan Julien sold the building to a young man named Tim Olson. He kept the original arts/crafts concept of the building and allowed all to remain in the building. At first our fear was that this unique building would be converted to condos or apartments. This was not to happen. Tim was in need of an onsite building manager and I was selected for the job. With my computer and photograph skills recently improved, I eventually became a full time employee of his for a number of years. At first I was only working 10-20 hours a week for him but as his holdings grew so did my hours of involvement with his business. I became very proficient with sales and marketing his properties. From brochures to advanced postings on Craig's List, I was his go to guy. I pioneered using YouTube to illustrate our available apartments to prospective tenants who not only saw great pictures but videos too. This was a winning concept that served his company for many years. With the downturn in banking industry and the economy in general, Tim like so many others lost a substantial amount of his holdings. My hours were trimmed back when he had to close his office. Last year in December, 2011 the bank foreclosed on the Arts Building. The new owner is an investment group from California called the CRE Group. I'm still the onsite manager of the building but it isn't clear if the new owners will continue the tradition started by Joan Julien so many years ago. I still do some sales and marketing for Tim and of course I still am doing what I love, crafting leather goods.

This May, I will be turning 65. Instead of retiring, I am focused on continuing to work while I still have my good health. Two broken marriages have taken a toll on me financially and the downturn of the leather industry in general has put pressure on me to continue as best as I can. When I first started in this love affair of leather working, I couldn't imagine the sorry state the leather industry is in today. With a vast amount of the industry gone not only from Wisconsin but from the entire USA, this industry is on it's last leg. In the news you hear that manufacturing is key to the success of America's economic growth but the pressure from abroad is fierce. The consuming public is fixated with their own economic troubles and the trickle down of available money is thin for spending it on handmade leather goods. Add the additional pressure that the organizers of the art/craft fairs put on us exhibitors I have a very clouded future.

With all the years of experience and the investment in material and machines, I have an advantage over anyone who would try to kick start a leather business in 2012. My daughter, Ann Marie has developed a website for me and we have looked at other ways to reach the buying public besides the art/craft fair circuit. Over the years, I have ridden many waves of success by following the popular business trends.

I look forward to many more years of being in love with crafting leather.

Click on This for A Short Video of Me