Having some cash to spend, I decorated it with some nice wood items made by my oldest and best friend Dick Ivens. I bought some beautiful oriental rugs and a scandanavia styled dining table. I liked being a bachelor and before long I met a new gal named Risé. She was an aspiring model and worked at a bank.

We turned each others head. Here she is giving her best head turn impression.

|

| My Sweetheart at the Time - Risé Anderson - 1974 |

As time wore on, I was getting a little older and wiser. One of the things I wanted to learn was how to make shoes. I was very good at making sandals, purses and garments but shoes were a whole new ball game. Leather working friends from Minneapolis had learned how to craft shoes from an old shoe maker that passed on his skills to them. One friend in particular, Jim Nikora gave me the low down and the inside knowledge on how to make a pair of shoes. This was purely an exercise in craftsmanship and not a venue for making any money. The amount of time and effort needed to make custom or even stock shoes were out of my reach. For each individual foot size, width and style a wooden last would be needed to wrap the leather around. For all those reasons, I could never have offered them for sale but I did make several pairs of shoes and boots for myself. Here is my first and second pair of shoes. The first pair were very basic and very brown from calfskin. Frank Zappa sang a sung that went like this: "Brown shoes, don't make it. Quit school, why fake it"? The second pair were made from horsehide.

|

| My First Two Pairs of Shoes I Made - 1974 |

To make a pair of shoes or boots, one first starts with a drawing.

Here's my drawing and pattern for a pair of boots.

|

| A Pattern for a Pair of Boots - 1974 |

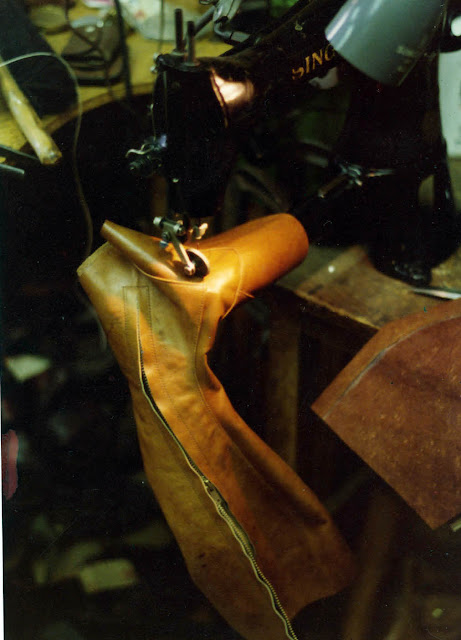

Exact measurements are taken of all parts of the foot, ankle and in this case my calf and how high the boots will be. This pattern is laid out onto the leather and stitched together. Seams need to be thinned and turned back and zippers or decoration has to be added. Here is a picture that is showing me sewing the upper parts together on a cylinder arm machine with a roller foot. The cylinder allows me to work on a curve and the roller foot allows me to stay very close to the edge of the leather.

|

| Stitching the Upper Parts on a Cylinder Arm Machine - 1974 |

Once the upper part is assembled I would turn my attention to the mid-sole and lower sole of the boot.

A leather welt would have to be hand sewn on the mid-sole so I could combine the upper to that mid-sole.

Several strategically placed grooves and channels were needed to be placed in the mid-sole to allow this to happen. It was very hard on my hands and I know now why old time shoe makers hands looked so worn and abused.

|

| Preparing the Mid-sole on Boots - 1974 |

Here is what the welt, mid-sole and uppers look like when they are hand stitched together. The knife is trimming off the excess of the uppers. Notice the heel area is being held together with nails that clinch back into the mid-sole because there is a metal plate on the bottom of the last at the heel, just for that purpose. The arch area between the end of the welt and the clinched heel would have a steel arch support laid in there, secured with two tacks and cemented over. Wooden pegs would also be added for strength.

|

| Trimming The Upper Material from the Mid-Sole - 1974 |

Another view of the mid-sole with the steel arch inserted and cork was used to fill up any spaces between the mid-sole and out-sole. The cork also helped in preventing the boot/shoe from "squeaking" when used.

|

| Mid-Sole with Steel Arch Support and Cork Padding - 1974 |

Once the mid-sole was completely finished on both feet, the out-sole would be attached. The welt stuck out from the mid-sole and provided a space for the out-sole to be attached. Here is the out-sole and the heel just before it was attached.

|

| Out Sole and Heel for Boots - 1974 |

Making shoes or boots was a great experience and I learned a lot about different types of construction.

I think it helped me look at other leather projects as just a process of one step after another. If I scaled it down to the step by step process, I can build anything!

No comments:

Post a Comment